Bending, Day 3

|

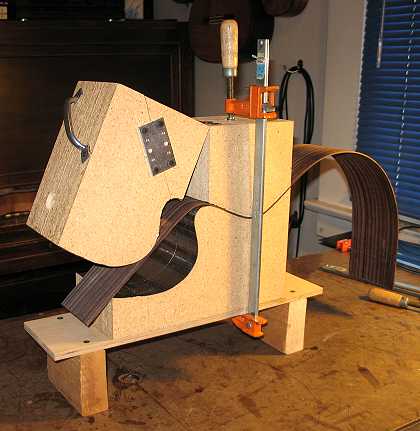

To the left is a photo of how I will begin the bending of the cutaway horn. When I do the actual bending, I will have everything wrapped in its "sandwich" again. The waist will be clamped down first. When the steam starts to appear, I will slowly push down on the left-hand section, adding a second clamp when possible (notice how I have added a handle --- which I will reverse, to make it more user-friendly --- when I screwed it in yesterday, I wasn't thinking of which side I would actually be working from). I will clamp down on that section, then add a third clamp horizontally to snug it all up. I'll do all this after I return from church. |

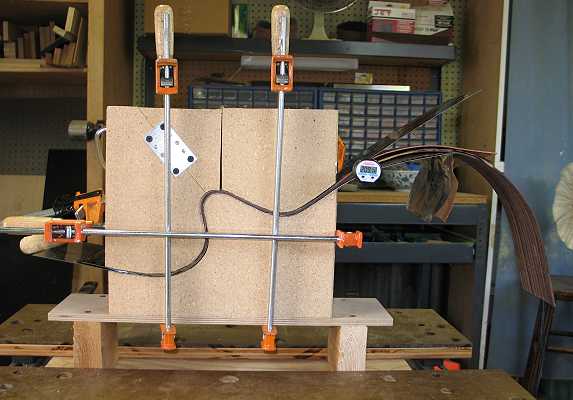

Okay, here's the cutaway side in the bender, after I've gone through the process described above. Just as I did on the regular bender, I went through about 3 cycles of heating up to around 310°, unplugging the blanket, and plugging it in again.

|

It looks good, as far as I can tell. I didn't hear anything cracking --- but it's hard to tell exactly what's going on, when you can't really see inside that sandwich. I'm keeping my fingers crossed....oh, the constant suspense of guitarmaking!!!

|

Previous PageNext Page |