Peghead, Begin Heel Work

I marked the 1/2" thickness of the peghead and where it will scoop down to form the volute.

After first cutting close to the line with my bandsaw, I then used the belt sander to sand up to the line and form the volute. Later this will be sanded to form the curved bottom of the peghead rear.

|

|

Next, in preparation for doing the preliminary neck angle work, I used the table saw to cut the end of the neck blank at the 14th fret position.

|

Previous PageNext Page |

I used the belt sander in its vertical position to sand the proper angle on the heel (I use a flat butt joint). I hold the neck blank against the miter gauge and actually use both hands as I'm sanding the heel. (This photo was just to show you how I use the belt sander; I wasn't actually sanding here!)

|

|

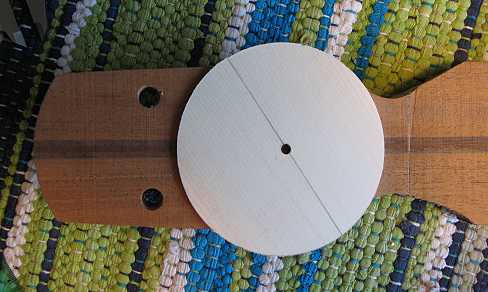

After a few tries, I got the angle right. Here I am checking it with a simple MDF straightedge. I want barely any space between the straightedge and the top at the saddle position. The neck angle and centering of the neck will be fine-tuned later, after I carve the neck and am able to bolt the neck to the soundbox.

|

|