Threaded Inserts, Trim Neck

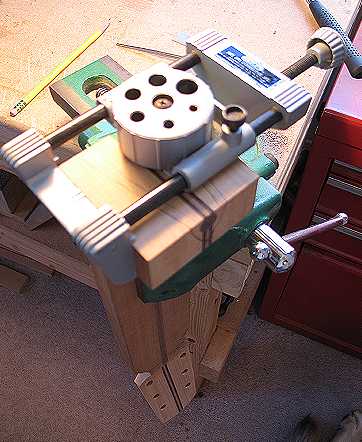

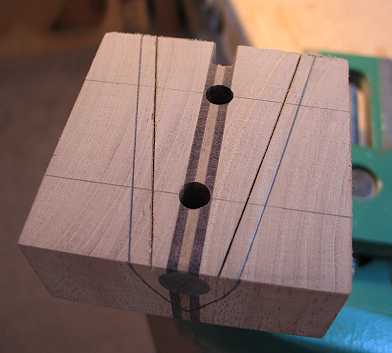

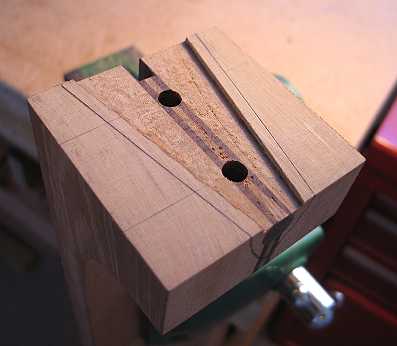

After the 5/16" holes for the inserts were drilled, I scribed two lines 3/16" inside the edges of the heel. I used my Dremel with the router base to rout out a 1/16" deep inner area. That way, the only part of the heel that will meet the soundbox will be those two 3/16" edges, making it easier to do the final fitting of the neck to the body.

|

|

These are the inserts and bolts I use:

They are readily available at any Ace Hardware store. The threaded insert accepts a 1/4-20 bolt; it is 1/2" long and is inserted into a 5/16" hole. It can be inserted with either an allen wrench (I forget at the moment which size) or this T-wrench (which has 1/4-20 threads).

I first used the T-wrench to install the threaded insert. Then, I used the allen wrench to carefully remove the insert, being careful not to disturb the threads in the wood. I dripped some superglue on the sides of the hole and then re-installed the inserts.

|

The final thing I did today was to trim the neck blank to around 1/8" outside the fingerboard and heel lines already marked.

Tomorrow, I will take a little break from this neck and will start work on the fingerboard — inlaying the position and side dots, fretting the fingerboard, and trimming the end of the fingerboard. Then will come doing the inlay on the peghead and carving the neck!!!

Previous PageNext Page |