Beginning the Top Bracing

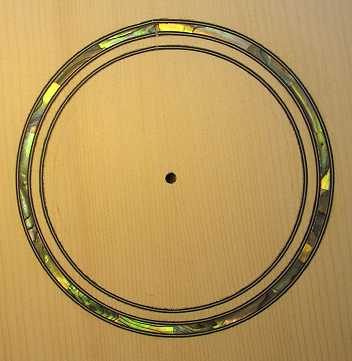

Friday, July 18th, 2008: Today I laid out the bracing plan on the top.

|

Then I started on the bracing. I first cut the lap joint on the x-braces and glued them down. This was the first time using my swivel go-bar deck, and it was wonderful!!! It made it SO much easier to apply the go-bar sticks to the different legs of the x-brace, and it was also much easier to get at the glue squeeze-out. All I had to do was turn the deck around to get at the different areas.

|

|

While that was in the go-bar deck, I decided to do a little bit on the neck blank. I drilled the hole for the 1/2" dowel in the heel (to give the threaded inserts for my bolt-on neck something to bite into other than end grain). Then I glued in the dowel. I also cut the taper on my ebony fingerboard (1-3/4" at the nut end and 2-1/8" at the 12th fret), using my fingerboard taper jig . |

Next, I glued a piece of spruce on top of the x-brace lap joint area, which I will carve later when I carve the x-braces. I also glued in the upper transverse brace and the brace above that (I always forget what it's called). These two braces I glue flat, whereas the x-brace and tone bars I glue with the 25' radius on the gluing surface.

|

|

The last thing I did for the day was to shape the x-braces and the upper transverse brace, and then to glue the two tone bars and finger braces (I think that's what they're called). Tomorrow I will shape those. Then it will be time to make and glue in the bridge patch and soundhole braces. At that point, the top bracing will be finished!!!

|

Previous PageNext Page |