Monday, June 25th, 2012:

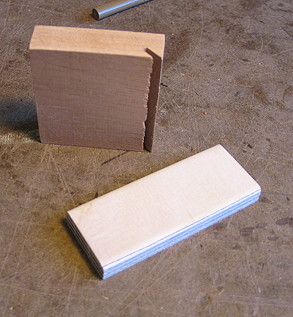

Now that the sides were bent, it was time to work on the neck and tail blocks. Below you see the mahogany neck block, with the 45-degree angle cut into it on my table saw, and the tail block, made of 3/8" birch plywood.

|

|

Here is a little jig I made today to make clamping and sawing off the ends of the sides a little easier. I saw it on Jon Sevy's excellent guitarbuilding site. It's basically just a big block with two narrow blocks that are attached with carriage bolts and wingnuts. I can use this for clamping a side so I can accurately trim (with either a plane or saw, as you see to the right) the ends of the sides. I will also use it later to clamp the tail block when I glue it to the sides.

|

|

(I'm actually right-handed; I'm holding this saw with my left hand only because I need my right hand to snap the photo.) |