Wednesday, July 4th, 2012:

LOTS OF PHOTOS TODAY!!!

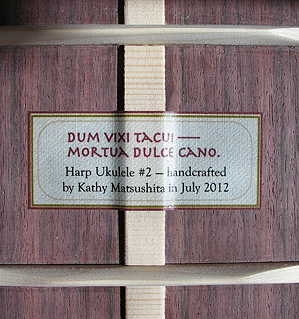

(1) The first thing I did today was to make my label. I printed it up on some linen paper, sprayed it with some shellac as a sealer, and let it dry for a while. Then I used some spray adhesive to glue it onto the back.

(3) However, as you can see in the two photos below, I did manage to chip out the spruce in a couple of places. Luckily, the chip-out was minimal, and was narrower than the binding ledge I will rout out later.

|

|

(2) Next, it was time to trim the overhang on the top. I wanted to do this now, so I could see how square the top was to the sides. It turned out to be almost perfectly perpendicular to the sides! To trim the overhang flush to the sides, I used my mini-drawknives and the cute little mini-plane I got from Stephen Boone. As I trimmed the overhang, I was careful to follow the grain.

|

|