|

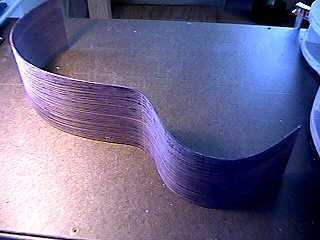

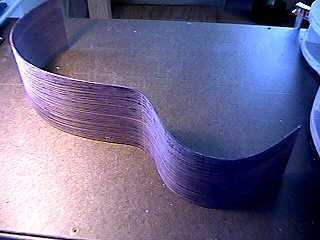

Well, here's the practice walnut side (actually,

only a portion of a side, as the walnut piece was only 18"

long). I LOVE USING THE HEATING BLANKET!!! The wood bent so easily

and quickly, there was no scorching (that dark area you see was

just where the store label was peeled off), no ripples -- just

a nice, smooth, even bend.

|

Here's the whole set-up, after I have removed

the bent side from the form.

Now I'm going to try out the mahogany practice

piece....

|

|

To the right, you see the tail and neck blocks

are glued to the sides. I have drilled the two holes for my

bolts which will attach the neck.

|

THE REAL THING:

|

July 3, 1999.....Well,

I bent the rosewood sides yesterday. It went really well.

To the left you see one of the sides, after I have let it sit

clamped in the mold overnight. I took the side out of the bender

as soon as it had all cooled down --- it didn't take long. It

only took about an hour. I must have made the bending form the

right size (I made it slightly smaller than the guitar template,

to account for the thickness of the heating blanket and the side),

because it fit the mold just about perfectly!

Today I trimmed the ends of the sides to fit inside

the mold and then made my neck and tail blocks. Right

now they're all glued and clamped up to the sides in the mold.

|

|

|