Saturday, August 11th, 2007: Okay, now it was time to work on the peghead! The first thing I did was to mark up the neck with the centerline and the tapered outline of the fingerboard. I put masking tape on the ebony headplate to more easily see the centerline.

|

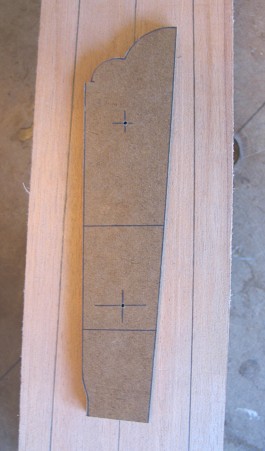

Next, I made a half-template of my peghead shape. (The lower "x" mark is wrong --- the line below that one is where I needed to drill the lower 5/8" hole for the slot! Luckily, I realized this before I actually drilled out the holes. The center line is where the middle tuner roller will be.) Using the half-template, I first traced the peghead outline onto the peghead. Then I used my bandsaw to rough-cut the outline. I did the sides first, ebony overlay up (I like seeing the front, instead of the back, when I do this). Then, I flipped it over, marked the crest outline on the back --- this way, when I bandsaw that section, the cut will be perpendicular to the face --- and bandsawed the crest. I finished it up with a chisel, file, and sandpaper. (The photo below is the result --- actually, it's a picture of the peghead after I had drilled the tuner holes --- I forgot to take a photo before that!)

|

Now, time for the tuner holes. I used a jig an Internet friend, Greg, had made for me a long, long while back. At first I thought I couldn't use it, because the bushings were 3/8"diameters, instead of the 13/32" I needed for these classical tuner rollers. I was going to try to use it after unscrewing the bushings, but there was too much "play" in the original holes. Then I found and read the directions he had sent me with the jig. (Duh! It helps to read directions.) He had suggested drilling the 3/8" holes first, then removing the jig and using a non-bradpoint 13/32" drill bit to enlarge the hole to the proper diameter. He said the non-bradpoint bit would naturally follow the 3/8" hole. So, I first tried it on some scrap wood --- it worked! Problem solved!

|

|

After that was done, I used a Forstner bit to drill out the 5/8" holes for the ends of the slots.

|

I first used a coping saw to rough-cut the slots, then a chisel to even out the sides. I used a file and sandpaper to finish it up. I had a little bit of chip-out on the inner sides of the tuner holes, but hopefully it won't be too noticeable. Here it is! I'm using Hauser-style Schaller tuners. Tomorrow, I'll use a round file to do the ramps on the lower part of the slots. Then I'll turn my attention to working on the fingerboard.

|

|

Previous Page |