Still Saturday, about 4:30 p.m. . . .

Top Binding Ledges

After a little break, I routed the top binding/purfling ledges. Since I had just routed the binding channel on the back, my router was already set up for the binding; thus, I started by routing out the top's binding ledge. I routed only up to the beginning and ending points of the arm bevel.

Then I followed that by routing the purfling ledge, which, unlike the back purfling, was a little bit thicker at .060".

I actually prefer routing the binding ledge first, as it gives you more area for the router jig's plastic "donut" to ride upon.

|

|

After the ledges were routed out, I used a file to smooth out the transitional areas between where the regular binding strip will be and where the arm bevel veneer and purflings will be.

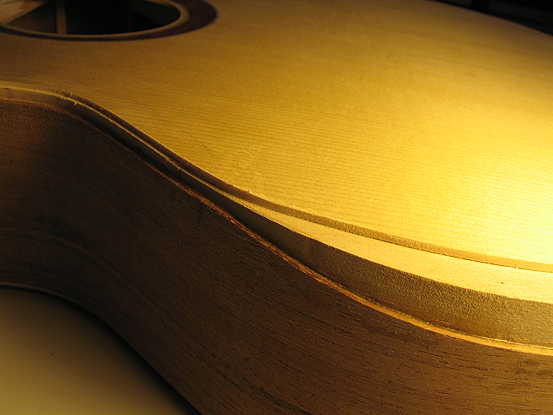

Here's how the binding and purfling fits on the top:

I think that's it for today --- my brain and nerves are shot. Time to eat some dinner and watch me some Netflix!!! |

|

Sunday, March 16th, 2014:

The End Wedge (Or Whatever This Shape Is)

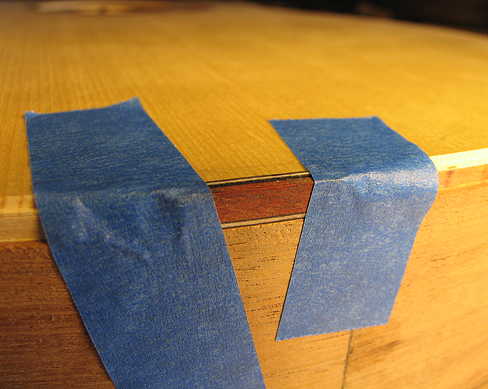

Instead of a regular end wedge shape, I decided to do a kind of flared-out shape, to repeat the theme of the various curves in this guitar (the curved arm bevel and the eccentric rosette).

Here I have made a paper cutout to see how it would look and what size it should be:

To create the shape, I drew a centerline on my bloodwood blank and used a compass (with its pivot point on that centerline) to draw two opposing curves with a circle radius of about 4-1/4". I drew the two curves so that there was 1" between them in the middle. Then I cut it out close to the lines on my bandsaw and used my spindle sander to sand right up to the lines:

|