Friday, March 7th, 2014:

Continuing on the Top

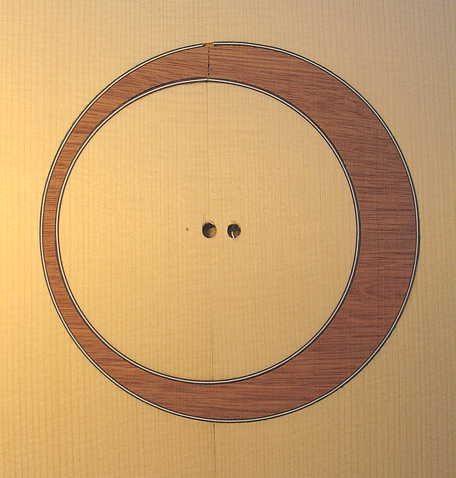

(1) When I got up today, the first thing I did was to sharpen my scraper (nothing like a nice, sharp scraper!!!). Then I carefully scraped the rosette down close to flush to the spruce.

|

|

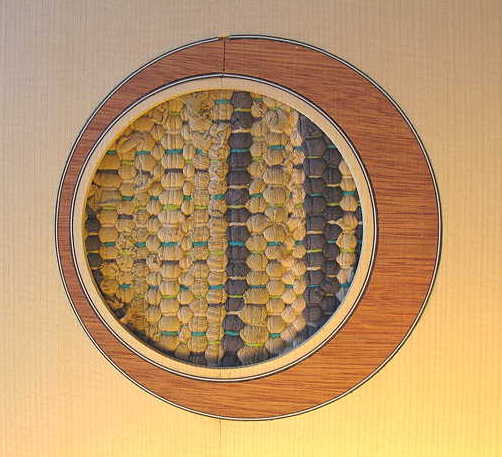

(2) Then I took it to the thickness sander, first sanding (with 120 grit on the drum) just enough to get the rosette truly flush to the spruce, so that all the purfling lines were nice and crisp.

After that, I flipped the top over and sanded the other side, little by little, until, when I shook the top plate (holding it loosely on both sides), it lost its initial stiffness, became floppy, and just started to sound like thin sheet metal when you shake it. (I can't think of how to describe the sound, except that it's kind of like a light "boing boing boing".)

I had just watched Kent Everett's DVD on voicing the guitar, and this is the method he uses to tell when to stop sanding the top. He says that that's when you can feel the top starting to become "musical".

My top ended up being around 7/64" (or .109") thick.

|

|

(3) Next, I cut out the soundhole.

|