Here's my fingerboard, after I've installed the frets. I seemed to have

lost ("misplaced"?) my fret

press caul (which I use in the drill press) -- I spent an hour unsuccessfully

looking high and low for it. So...I had to resort to hammering in the frets

using my deadblow

hammer. I run a small bead of Titebond glue on the tang before I pound

the fret in. Before I hammered in the frets, however, since this is a bound

fingerboard (bound in ebony), I had to undercut the tangs. This was easily

done using my Stew-Mac fret

tang nipper. It does such a clean job of it, it's a joy to use! I have

not yet trimmed the fret ends flush to the fingerboard.

Oh, yeah....In case you're wondering why my fingerboard is missing two

frets (the 3rd and 11th)....I haven't installed those yet, because I have

drilled two tiny holes in those two fret slots, so I can use tiny pins

(actually nail brads) to later position the fingerboard onto the neck.

I will install these two frets after I have glued the fingerboard to the

neck.

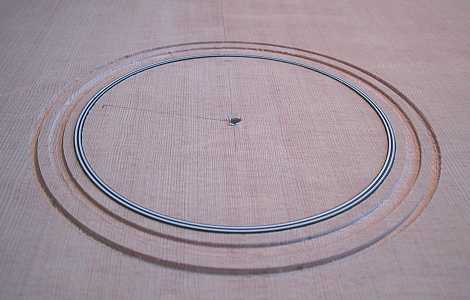

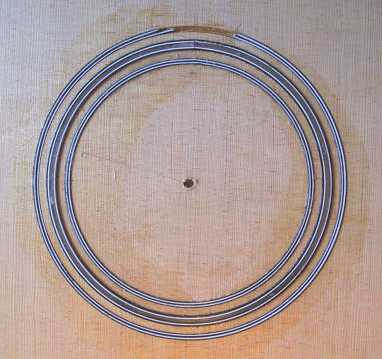

BELOW: Installing the frets puts a little backbow into

the fingerboard, so I always clamp the fingerboard straight using the method

below: