July 30, 2004 . . . . .

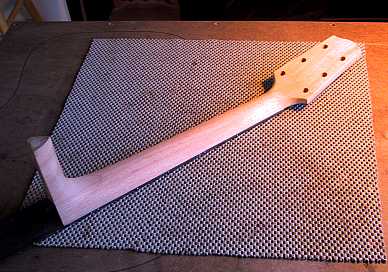

Now it's time to work on the neck again. I have carved the heel, primarily using my mini-drawknives I've had for years. Then I used a scraper ans 120-grit sandpaper to smooth out the tool marks. I must be getting better at this, because it felt a lot easier and went a lot faster than it used to.

BELOW I am gluing the fingerboard to the neck. I first inserted the Hot Rod truss rod, putting a few dabs of silicone bathroom sealer in the bottom of the slot, to cushion the rod. Then, as the Stew-Mac Hot Rod instructions suggest, I placed a strip of 3/4" wide masking tape over the rod, spread Titebond glue over the neck surface, and removed the tape. That way, when the glue spreads with clamping, it will just go to the edge of the truss rod slot and no further.

I then set the fingerboard on the neck (I had previously drilled two tiny brad holes through frets 3 and 11 to position the fingerboard properly on the neck) and clamped it up, using a fingerboard caul I had made years ago. The caul has slots at the fret positions, so there is just wood-to-wood contact.