Here I have routed the slots for the rods and have epoxied them in.

After this is dried and cured, I will scrape the surface flush and will then move on to routing the channel for the truss rod.

Once that is done, I will drill the holes for the threaded inserts and install those. (I like to do this before doing any bandsawing or shaping of the neck, because having the blank still square makes it very easy for me to use this dowel jig to drill the holes in their accurate positions and absolutely perpendicular to the heel face.)

After that is complete, I can finally move on to bandsawing out the neck shape and all the rest....

|

|

Saturday, March 22nd, 2014

Last night, as I mentioned, I used my dowel jig to drill the 3/8" holes for the two threaded inserts. I drill the holes a little over 1/2" deep; the inserts are 1/2" long, and I want to set them in about 1/16" (to account for the fact that I will later cove out all but the outside edges of the heel, for easier fitting of the heel to the slight curve where the heel meets the soundbox). What I do after drilling the holes is to first install the inserts dry, then screw them back out and drop some superglue onto the sides of the hole. Then I reinstall the inserts.

After I installed the threaded inserts, I took the blank to the bandsaw and cut out the basic neck profile, because, for routing the truss rod slot, I wanted to use this jig I've had for many, many years. (I got the idea from both John Mayes's and Jeff Traugott's sites.) It allows you to easily line up the neck for accurately routing the truss rod slot.

Here's the top of the jig. The router runs along the two wood strips. The router bit runs within the center slot of the jig. I put paste wax on the surfaces that the router contacts, so it will glide smoothly in the jig. The blue masking tape here tells me where I need to stop the edge of the router, so the slot stops at the nut end of the neck blank.

|

|

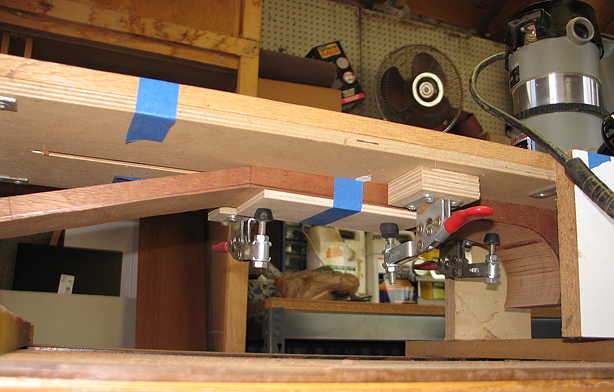

Here's the underside of the jig. The neck is held in place by three toggle clamps. I position the neck so that the truss rod slot-to-be is lined up exactly in the center of the slot in the jig.

Here's the end of the jig where the heel is located. I can easily adjust the depth of the router bit by simply sighting it from this end.

|