Wednesday through Friday, June 23-25, 2004:

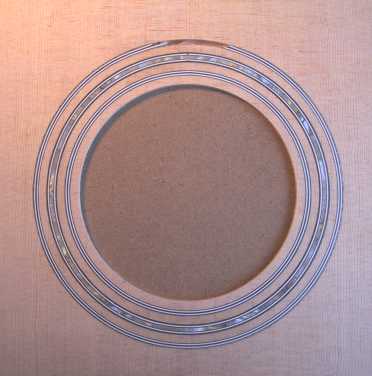

The first thing I did Thursday was sand down the rosette after I had let the abalone purfling ring cure.

I had pulled out the teflon filler strip Wednesday, sanded down the plastic purfling rings, and then used Duco cement for installing the abalone ring. I think it came out nicely!