Session #16, #17, #18

|

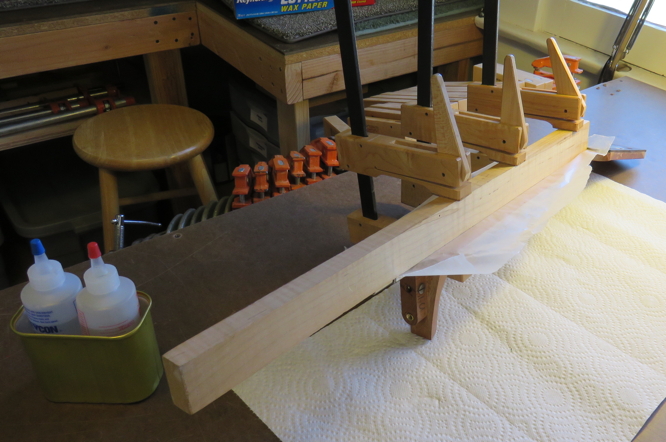

Monday, July 27th, 2015: SESSION #17: Only one photo today --- today Randall glued the fingerboard to the neck, after scraping the epoxy covering the truss rod flush with the neck surface.

|

Sunday, August 2nd, 2015: SESSION #18: Again, lots of work was done today. Today Randall carved the neck edges flush with the fingerboard edges, made his heel cap out of bloodwood, with a thin maple veneer which will coincide with the binding's purfling line, and pore-filled the neck.

|

|

|

|

|

||

|

|

|

|

|

Previous Page |

Table of Contents |

Next Page |